INCONCRETO NEWS

From Executors to Strategic Enablers: Industrial Robots Today

Industrial robotics has long been associated with automation, productivity gains, and cost reduction.

This was true when robots appeared in manufacturing. The first commercially successful industrial robot, Unimate, was deployed in 1961 on a General Motors assembly line in Trenton, New Jersey, to handle tasks that were dangerous or monotonous for human workers, such as unloading die-cast metal parts from production equipment. This early application marked the beginning of a long trajectory in which robots were used to execute repetitive, hard-coded tasks in factories, especially in automotive and heavy industry.

For decades, industrial robots were typically programmed to perform predefined sequences of movements with high precision and endurance, contributing to productivity gains, cost reduction, and improved worker safety. Initially focused on welding, material handling, and assembly tasks in sectors such as automotive and electronics, these robots became a foundational element of modern manufacturing automation.

Over the past years, the landscape has shifted dramatically. Advances in sensing technologies, artificial intelligence, and connectivity have enabled robots to operate with far greater flexibility, autonomy, and responsiveness than before. Instead of functioning only as isolated machines executing fixed instructions, modern robots are increasingly embedded within broader industrial systems. They collaborate with human operators, interact with other machines, and support data-driven processes. As an example, Amazon now operate hundreds of thousands of robots across their global fulfilment centres, performing tasks from transporting goods to sorting items and assisting with packaging, often in coordination with human teams.

These developments illustrate that robotics has become a strategic topic influencing capital investment, workforce organization, supply chain operations, and industrial competitiveness.

Understanding how robots are evolving – both in terms of function and impact – is essential for industrial leaders looking to make informed decisions about investment, transformation, and long-term positioning.

Beyond Automation: How Robots Contribute to Industry Today

For much of their industrial history, robots were primarily deployed to automate predefined tasks requiring speed, precision, and consistency. This role remains central, but on its own it no longer captures the full contribution of robotics to industrial performance. Today, robots fulfil a variety of functional roles within industrial systems, shaped by changes in technology, organization, and strategic priorities.

The foundational role of industrial robots remains the execution of repetitive, standardized tasks in controlled environments. Traditional applications such as material handling, welding, painting and routine inspection continue to be widespread on factory floors, especially in automotive and electronics production. Recent industry analysis based on the World Robotics 2025 by Industrial Robots report confirms that factories around the world still rely heavily on robots to improve efficiency and reliability in these core functions.

In practice, in sectors like automotive, many deployed robots are currently used for lower-level operational tasks such as quality checks, light assembly and routine inspections. In these contexts, robots deliver productivity gains, quality consistency, and improved worker safety by taking on hazardous, repetitive, or physically demanding work.

This execution-focused model, however, increasingly coexists with more flexible and interactive forms of robotic deployment as new technologies mature.

Robots as Collaborative Partners and the Rise of Intelligent Automation

One of the most visible shifts in industrial robotics over the past decade has been the rise of collaborative robots, or cobots. Unlike traditional industrial robots, which typically operate in fenced-off areas, cobots are specifically designed to work safely alongside human operators, often without physical barriers. This is enabled by force-limiting designs, advanced sensors, and dedicated safety standards, which provides the regulatory framework for safe human-robot interaction.

Cobots are commonly deployed to assist with tasks such as component positioning, screwdriving, quality inspection, packaging, and machine tending. These applications combine human judgment with robotic precision, improving ergonomics, consistency, and productivity. The approach is particularly attractive for small and medium-sized manufacturers and for high-mix, low-volume production environments, where flexibility and human expertise remain critical.

In practice, cobots redistribute tasks between humans and machines, enabling workers to focus on higher-value or supervisory work rather than repetitive, physically demanding activities.

The market share of cobots reflects their growing importance: in 2023, collaborative robots accounted for 10.5% of the total 541,302 industrial robots installed worldwide. The International Federation of Robotics indicate that cobots are complementary to traditional industrial robots rather than a replacement. Conventional robots, which operate at higher speeds, remain essential for productivity in high-volume or margin-sensitive manufacturing environments.

This highlights the dual role of robotics today: traditional robots for speed and efficiency, cobots for human-centred flexibility and adaptability.

Robots as Adaptive and Strategic Partners in Industry: Learning, Perception, and Flexibility

While traditional industrial robots and cobots extend human work safely and predictably, the next wave of robotics is pushing collaboration and autonomy further.

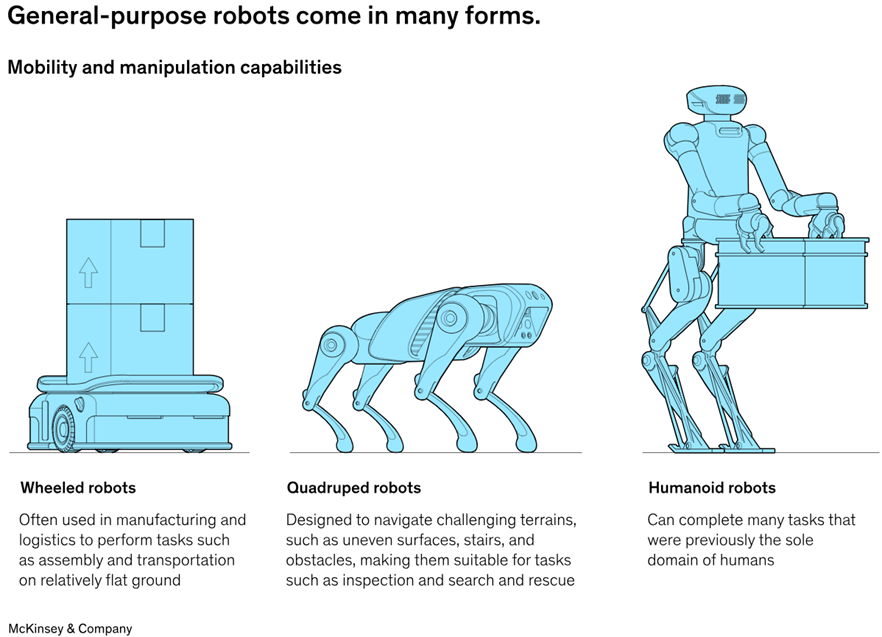

McKinsey describes general-purpose robots as systems that combine AI, perception, and learning capabilities, enabling them to operate in variable, unstructured environments, perform multiple tasks, and adapt dynamically without extensive reprogramming. In effect, these intelligent robots build on the foundations of cobots, combining physical collaboration with autonomous decision-making, and representing the emerging frontier of human-centred industrial automation.

These AI-enabled systems are increasingly deployed in production tasks such as bin picking, quality inspection, and sorting, where objects vary in shape, orientation, or condition. Rather than relying exclusively on hard-coded instructions, they can learn from data or human demonstrations, significantly growing the range of industrial tasks that robots can perform reliably. While these developments do not imply full autonomy in the human sense, they enable adaptive, collaborative workflows that integrate robots as partners in operational, organizational, and strategic dimensions of manufacturing.

The expansion of robotics going beyond production. Autonomous Mobile Robots (AMRs) now play a critical role in industrial logistics and material flow, transporting goods, managing inventory, and supporting order fulfilment in factories, warehouses, and distribution centres. Unlike traditional automated guided vehicles (AGVs), AMRs can navigate dynamically, adapt to changing environments, and integrate with warehouse management systems. As a result, they enable flexible, scalable, and resilient logistics operations.

Some examples will tell us to what extent AMRs are already ensuring a positive impact. DHL highlights robotics as a key enabler of operational resilience and scalability in logistics. For instance, the company has deployed over 1,000 autonomous robots across its UK operations to transport goods, manage inventory, and support order fulfilment in dynamically changing environments. These robots allow DHL to adapt quickly to demand fluctuations, maintain productivity despite labour shortages in this field, and optimize material flow in warehouses and distribution centres.

The World Economic Forum emphasize that warehouse automation is now a strategic lever: it addresses rising service expectations, supports rapid implementation in e-commerce environments, and mitigates the impact of labour shortages. Advanced systems integrate autonomous mobile robots (AMRs) with warehouse management software, enabling dynamic route planning, real-time inventory tracking, and coordination with human operators.

Amazon Robotics provides a high-profile case of industrial-scale AMR integration. Its 10 types of robots move shelves and bins to human pickers or packing stations, dramatically reducing walking time, increasing throughput, and stabilizing warehouse flows in facilities with high product variability. This combination of human-robot collaboration, AI-enabled scheduling, and autonomous navigation illustrates how logistics robotics can enhance flexibility, efficiency, and scalability in complex supply chains.

Together, these practices demonstrate that industrial logistics robots are now integrated enablers of operational efficiency, workforce augmentation, and strategic agility, capable of responding to fluctuating demand and reshaping the organization of material flow.

Robots as Engines of Industrial Intelligence

In advanced industrial environments, robots increasingly serve not just as physical actors but as generators and enablers of industrial intelligence. Modern robotics systems are embedded with arrays of sensors – covering vision, force, position, temperature, and environmental conditions – that continuously collect high-resolution operational data. Far from simply executing tasks, these data streams become the foundation for real-time analytics, predictive insights, and decision support across manufacturing processes.

One of the most prominent manifestations of robot-driven industrial intelligence is the digital twin concept. A digital twin is a virtual representation of a physical system or process, dynamically synchronized with sensor data from the factory floor. In smart manufacturing, robotic data feeds digital twins with continuous real-time information, enabling simulation, performance analysis, and predictive modelling. Such models support predictive maintenance, where anomalies and degradation patterns are identified before failures occur, minimizing unplanned downtime and enhancing system resilience. Digital twin integration also improves operational visibility, allowing managers to monitor entire production lines, anticipate quality deviations, and optimize workflows.

Robotic data also plays a central role in predictive quality control. By analysing patterns from historical and live production data, AI models can detect subtle deviations that might indicate quality issues, often before a human inspector could identify them. In this way, robots function as early warning systems, directing attention to systemic variances and reducing defect rates.

Beyond shop-floor optimization, the intelligence derived from robotics data supports strategic decision-making. Aggregated data insights inform capacity planning, process redesign, and investment prioritization. This enables industrial leaders to move toward proactive optimization of operations, integrating robotics into the broader enterprise intelligence architecture.

In this emerging paradigm, robotics become continuous sources of industrial intelligence, enhancing visibility, agility, and decision quality across production systems, elevating to strategic infrastructure at the heart of smart manufacturing. The integration of robotics into decision-making processes also raises important questions around responsibility, oversight, and governance, increasingly shaping how intelligent automation is deployed at scale.

These cutting-edge roles show that industrial robots combine mechanical capabilities with integration into organizational structures, information systems, and strategic decision-making. Such evolution creates the foundation for the growing role of artificial intelligence in robotics and reveals meaningful differences in how regions and industries adopt and deploy these technologies.

INCONCRETO’s Strategic Vision: Unlocking Value through Robotics and Intelligent Automation

Robotics and intelligent automation are transforming the way industries operate, shaping production, workforce dynamics, and strategic decision-making. Successfully harnessing these technologies requires coordinated planning across operational processes, digital integration, and human-machine collaboration.

INCONCRETO can accompany clients in the implementation of robotics solutions that drive efficiency, reliability, and resilience throughout industrial operations. Through foresight into technological trends and careful stakeholder alignment, we enable companies to leverage robotics not only to optimize current operations but also to build adaptive, data-driven systems that anticipate change. In doing so, INCONCRETO helps clients transform complexity into long-term competitive advantage, strengthening industrial ecosystems while advancing innovation across sectors.

For further reading, you may consult these sources:

- Types of Robots, by Intel

- Will embodied AI create robotic coworkers?, by McKinsey

- Collaborative Robots – How Robots Work alongside Humans, by the International Federation of Robotics

- Robots on the line: enhancing precision and productivity, by KnowledgeAgent

- A Guide to Autonomous Mobile Robots (AMRs), by Autostore

- Warehouse robotics: is this the moment of truth?, by DHL

- Intelligent robotic systems in Industry 4.0: A review, in the Journal of Advanced Manufacturing Science and Technology

- Artificial Intelligence in Manufacturing Research Report 2025-2030, by GlobeNewswire

Latest News

Semiconductors Today: Global Industry Dynamics and Strategic Value Chains

Mining Today, Powering Tomorrow: The Global Race for Transition Minerals

Newsletter

© INCONCRETO. All rights reserved. Powered by AYM