INCONCRETO NEWS

Traditional Applications of Hydrogen in Industry

The main differences between grey and green hydrogen

Hydrogen is the most abundant element in the universe, and it has a wide range of applications in various industries. It is commonly used as a feedstock in the chemical industry, as a reducing agent in metallurgy, and as a fuel for transportation and power generation. In this article, we will explore the traditional applications of hydrogen in industry and discuss the differences between grey and green hydrogen.

Hydrogen is a colourless, odourless, and tasteless gas, but the colour of hydrogen used in industry is not related to its visual appearance. Instead, it refers to the source of its production and the process used to generate it.

As it has been briefly illustrated in our publication of January, grey hydrogen is the most common form of hydrogen used in industry today. It is produced from natural gas or other fossil fuels through a process called steam methane reforming. This process involves reacting natural gas with steam at high temperatures and pressures, which produces hydrogen and carbon dioxide as by-products. The carbon dioxide is then typically released into the atmosphere, contributing to greenhouse gas emissions.

Green hydrogen is produced using renewable energy sources, such as solar or wind power, to electrolyze water. This process involves splitting water molecules into hydrogen and oxygen using an electrical current. The resulting hydrogen is considered green because it is produced without any carbon emissions.

The main difference between grey and green hydrogen lies in their environmental impact. Grey hydrogen is responsible for significant carbon emissions, making it a major contributor to climate change. Though green hydrogen has a much smaller carbon footprint and can be considered carbon-neutral or even carbon-negative if the renewable energy used in its production comes from sources that are themselves carbon-negative.

Despite its environmental impact, grey hydrogen is still widely used in industry due to its low cost and availability. It is used as a feedstock in the production of ammonia, methanol, and other chemicals, and as a reducing agent in the production of steel and other metals. It is also used as a fuel for heating and power generation.

Green hydrogen, on the other hand, is a relatively new technology and is not yet widely used in industry. However, it has significant potential to transform the way we produce and consume energy. It can be used as a fuel for transportation, power generation, and heating, and can also be used as a feedstock for the chemical industry.

If grey hydrogen still represents about 95% of current production, green hydrogen is set to play a leading role in the mix of renewable energies. Although challenges remain in terms of storage and profitability, green hydrogen has the potential to replace traditional fuels in all transport sectors, including aviation and shipping. It can be converted to produce substitute fuels such as ammonia and e-methane, and has also the potential to facilitate the transition of high-carbon industrial processes in sectors such as petrochemicals, steelmaking, and electricity production.

From a political point of view: the case of Europe

Green hydrogen is becoming an increasingly popular alternative to grey hydrogen. The European Union published its REPowerEU plan in 2022, making green hydrogen an absolute priority. The goal is to achieve 20 million tons of renewable hydrogen by 2030, half of which will be imported and the other half produced domestically.

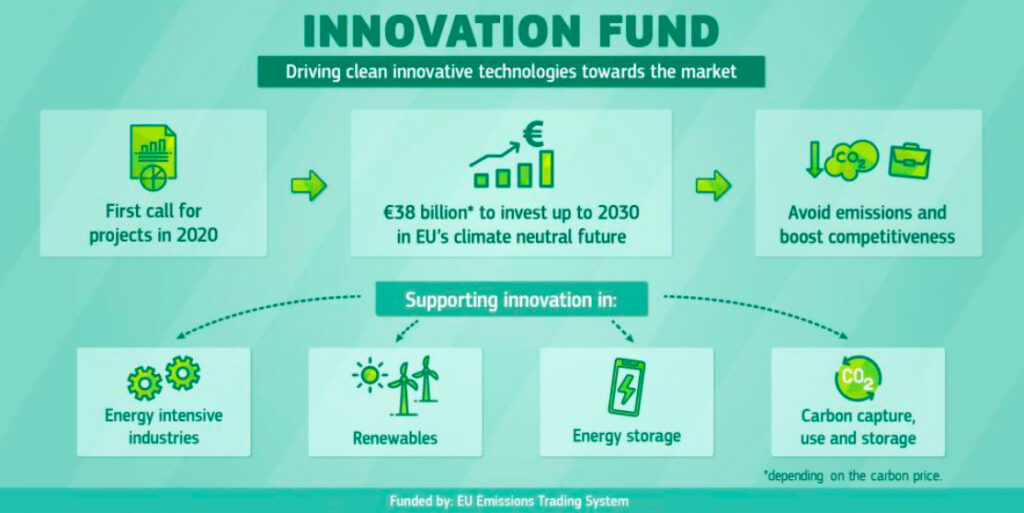

Today, the EU is investing over €62 million in 17 small-scale innovative clean-tech projects with a fourth round of awards under the EU Innovation Fund. Grants disbursed help bring breakthrough technologies to the market in energy-intensive industries, renewable energy, hydrogen, and energy storage. This will accelerate Europe’s clean energy transition and decarbonisation, across a large geographic spread and a wide variety of industrial sectors.

The Innovation Fund is one of the world’s largest funding programmes for the demonstration of innovative low-carbon technologies. The Innovation Fund will provide around EUR 38 billion of support from 2020 to 2030. The EU Emissions Trading System (EU ETS), the world’s largest carbon pricing system, is providing the revenues for the Innovation Fund from the auctioning of 450 million allowances from 2020 to 2030, as well as any unspent funds from the NER300 programm (the predecessor of the Innovation Fund).

Source: European Commission

The subsidies granted by governments aim to encourage the use of clean and sustainable technologies, such as renewable energy, electric cars, or thermal insulation of buildings. Without these subsidies, these options would often be more expensive than conventional solutions.

Moreover, the costs associated with energy transition are constantly decreasing thanks to technological advances and the increasing scale of production of eco-friendly equipment. Thus, although it may seem expensive in the short term, investing in clean technologies is increasingly profitable in the long term.

In summary, the political dimension in this situation consists of subsidizing ecological actions to encourage their adoption despite their high cost, to protect the planet and reduce greenhouse gas emissions.

Main industrial applications of hydrogen

Hydrogen has been utilized in a variety of traditional applications for decades, and it continues to play a dominant role in the industrial sector. Two major areas where hydrogen has traditionally been used are the petroleum refining industry and the agricultural/chemical industry.

In the petroleum refining industry, hydrogen is used in the process of de-sulfurization. Crude oil is refined to produce petrol and diesel, among other chemicals. During this process, sulfur is removed from the crude oil, which is a crucial step in ensuring the final product meets regulatory standards. Hydrogen is an essential component in the de-sulfurization process, as it reacts with the sulfur present in the crude oil to produce hydrogen sulfide. This hydrogen sulfide is then easily removed from the crude oil, resulting in a clean and high-quality fuel product.

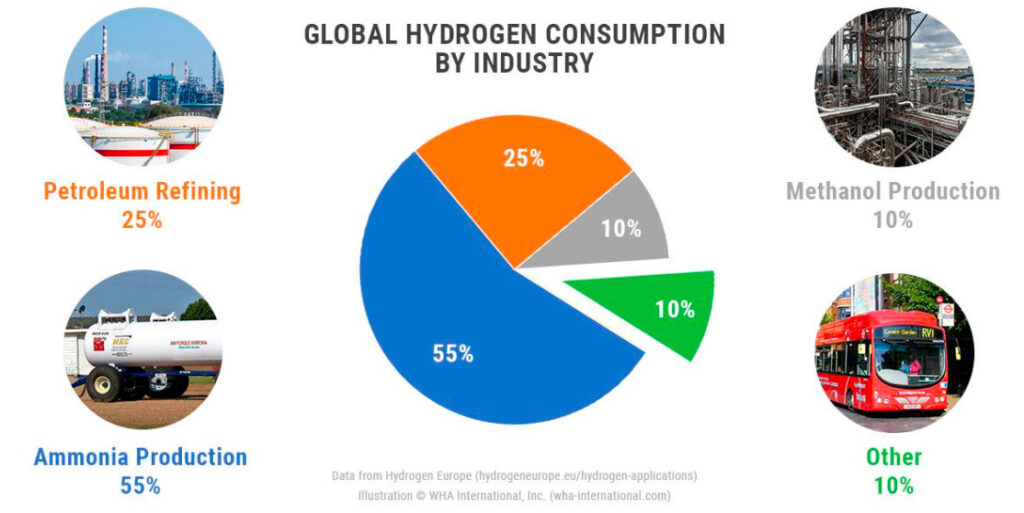

In the agricultural and chemical industry, hydrogen plays a vital role in the production of ammonia. Ammonia is an essential component of fertilizer and is used to promote plant growth. Hydrogen is the basis of ammonia, and it is combined with nitrogen in the Haber-Bosch process to produce ammonia. Ammonia production accounts for over 50% of the hydrogen used worldwide This process has revolutionized the agricultural industry, as it has allowed for the production of large quantities of fertilizer at a relatively low cost.

Despite the many advantages of using it, hydrogen is a gas, which means that it requires a lot of space to store and is difficult to transport. However, ammonia, which is made up of hydrogen and nitrogen, is much easier to handle. It is a liquid at room temperature and pressure, which means it can be stored and transported much more easily than simple hydrogen gas. As a result, ammonia has emerged as a viable alternative for storing and transporting hydrogen.

Overall, the traditional applications of hydrogen have played a critical role in the industrial sector for many years. From the refining of crude oil to the production of fertilizer, hydrogen has been a vital component for many essential products. However, the issue of storage and transportation has always been a concern. With ammonia now evolving as a sustainable option for storing and transporting hydrogen, we can expect to see more widespread use of hydrogen in the future. As the world continues to move towards a more sustainable future, hydrogen and its many applications are sure to play a crucial role.

According to Hydrogen Europe, the European association representing the interest of the hydrogen industry, about 55% of the hydrogen around the world goes to ammonia production; 25% is used in refining and about 10% is used to produce methanol. Other applications only account for about 10%.

Other traditional applications of hydrogen

Beyond just the petroleum refining and agricultural/chemical industries, let’s take a closer look at some of the other common uses of hydrogen in industry.

One significant use of hydrogen is in food processing. Hydrogen is often used as a protective gas in the packaging of certain foods, such as potato chips and coffee beans. This is because hydrogen is an inert gas, which means that it does not react with the food product or cause any undesirable changes in flavor or texture. In addition, hydrogen can also be used to create artificial sweeteners, such as saccharin, which is commonly used in diet soda.

Hydrogen also plays a crucial role in the metalworking industry. It is often used as a shielding gas in welding, as it prevents the metal from being contaminated by the air. This is especially important when welding materials that are sensitive to oxidation, such as aluminium and stainless steel. Additionally, hydrogen is also used in the production of certain metals, such as titanium.

The electronics manufacturing industry also relies heavily on hydrogen. Hydrogen is used in the production of flat panel displays, such as those used in televisions and computer monitors. It is also used in the production of semiconductors, which are essential components of electronic devices such as smartphones and laptops.

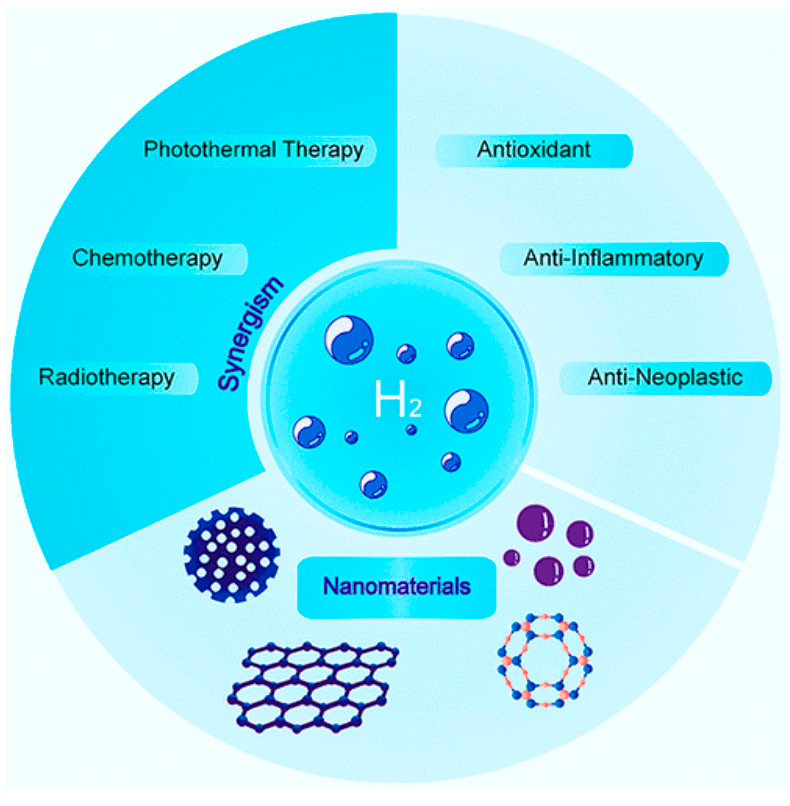

Another critical application of hydrogen is in the medical field. Hydrogen is used in cancer treatment, specifically in radiation therapy. When used in conjunction with oxygen, hydrogen can enhance the effectiveness of radiation therapy and reduce the amount of damage to healthy cells. Hydrogen is also used in the production of certain medications, such as cholesterol-lowering drugs.

Hydrogen therapy is a highly promising strategy against several diseases due to its inherent biosafety.

Source: https://pubs.acs.org

In conclusion, it’s evident that the world is actively seeking sustainable and environmentally friendly alternatives, and the use of hydrogen in various industries is poised to increase significantly. Hydrogen is a crucial component in the production of a wide range of essential products, from agriculture and food processing to electronics manufacturing and cancer treatment, making its demand more prevalent than ever before.

The need of the hour is to focus on developing the production of green hydrogen, despite the high cost, as this will help safeguard our planet and drastically reduce greenhouse gas emissions.

INCONCRETO, as an international consultancy, can provide expertise in capital project optimization and oversee critical paths for innovative industries.

Connect with our team!

We combine technical expertise with large program execution practices, improving predictable outcomes and steering profitability on Capex/Opex project investments.

For further reading, you may consult these sources:

https://www.rte-france.com/wiki-energie/hydrogene-vert-mythe-realite

https://hydrogeneurope.eu/mission-vision/

https://wha-international.com/hydrogen-in-industry/

https://pubs.acs.org/doi/10.1021/acsnano.9b05124

https://ec.europa.eu/commission/presscorner/detail/en/ip_22_7667

https://group.bnpparibas/actualite/hydrogene-vert-la-belgique-chef-de-file-en-europe-occidentale

Newsletter

© INCONCRETO. All rights reserved. Powered by AYM